Chuangxin Road, High-tech Zone, Xi'an City, Shaanxi Province, China

Titanium in Aerospace

Titanium is a popular choice for aerospace applications because of its outstanding properties, including a high strength-to-weight ratio, excellent corrosion resistance and excellent heat resistance. From structural components to fasteners, titanium products are helping to develop lighter, stronger and more efficient aerospace systems.

Benefits of Titanium Alloys in Aerospace

- • High reliability

- • Low thermal expansion rate

- • Superior strength-to-weight ratios

- • Corrosion resistance

- • Ability to withstand high temperatures

- • Impressive mechanical properties

- • Fatigue Resistance

- • Excellent Formability

Structural Air-frame Applications

Titanium is an excellent choice for air-frame applications that require a strong, lightweight material. Its unique features make it ideal for use in wings, landing gear and other engineered parts. In addition to its strength-to-weight ratio, titanium also offers superior fatigue resistance, resistance to corrosion and insulation properties. Titanium components are regularly used in essential aviation structures including fasteners, springs and hydraulic tubing.

Commercial Rotorcraft

Titanium is an economical choice for this commercial application due to its excellent strength-to-weight ratio and reliability during use.

Titanium alloy has the characteristics of high strength, good corrosion resistance and high heat resistance. Using it to make light aircraft can greatly reduce the weight of the aircraft and increase its endurance.Titanium has been successfully used in several helicopter programs around the world.

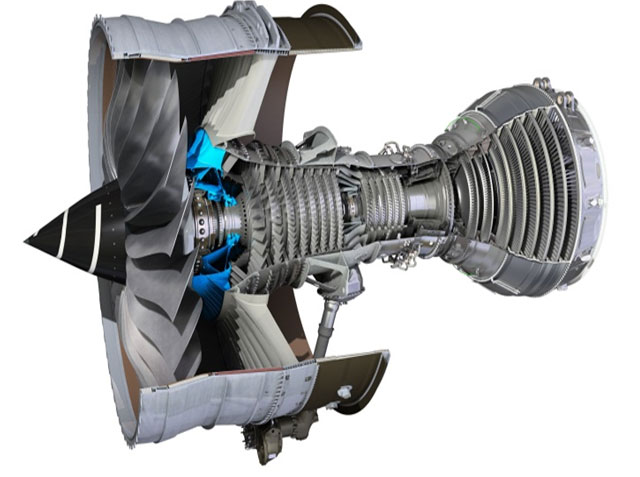

Aircraft Engines

Titanium boasts an impressive strength-to-weight ratio, outstanding abilities in high temperature functions, and superb corrosion resistance. As such, it is a natural fit for use in aircraft engines, as parts made from titanium can withstand temperatures of up to 1100°F (593°C). As a result, Titanium is commonly the material of choice for engine components subjected to such rigorous conditions.

Titanium is widely used in engine components, representing 20-30% of the dry weight. This metal is ideal for designs that require high strength and lightness simultaneously, like blades, discs, hubs, inlet guide vanes, and cases. Titanium alloys provide superior performance compared to other metals such as stainless steel or aluminum.

Space Structure Applications

Titanium alloy is a new important structural material used in the aerospace industry. The amount of titanium alloy used in aeroengines usually accounts for 20% to 30% of the total weight of the structure. It is mainly used to make compressor parts, such as cast titanium electric fans, compressor discs and blades, cast titanium compressor casings, intermediate casings, Bearing housing, etc.

Spacecraft mainly use the high specific strength, corrosion resistance and low temperature resistance of titanium alloy to make various pressure vessels, fuel tanks, fasteners, instrument straps, structures and rocket casings. Artificial earth satellites, lunar modules, manned spacecraft and space shuttles also use titanium alloy plate welding parts.

ENTORUST CERTIFICATION

We are follow the quality system and standards strictly.approvals from most leading OEM’s across Aerospace, Medical, Industrial, and Oil and Gas markets.

.jpg)