Chuangxin Road, High-tech Zone, Xi'an City, Shaanxi Province, China

Titanium In Medical Industry

Titanium is the preferred material for a variety of medical applications because of its superior properties. Its biocompatibility, non-toxicity, impressive corrosion resistance, and strength make it ideal for artificial bones, heart valves, pacemakers, surgical instruments, dental roots, and shape memory alloys. These properties make titanium an optimal choice for the healthcare industry.

- • Resistance to corrosion

- • Biocompatibility

- • Superior mechanical and durability properties

- • Toughness

- • Low elastic modulus

- • Good wear resistance

- • High Strength-to-Weight Ratio

- • Osseointegration

- • Formability

- • Low Thermal Conductivity

Titanium is widely accepted in the medical industry for its excellent biocompatibility and strength. It outperforms stainless steel and cobalt chrome on both counts, making it the metal of choice for many applications where reliability and performance are paramount. Titanium also has a higher fatigue limit than many other metals. This makes it an ideal material for medical applications where durability and safety are essential.

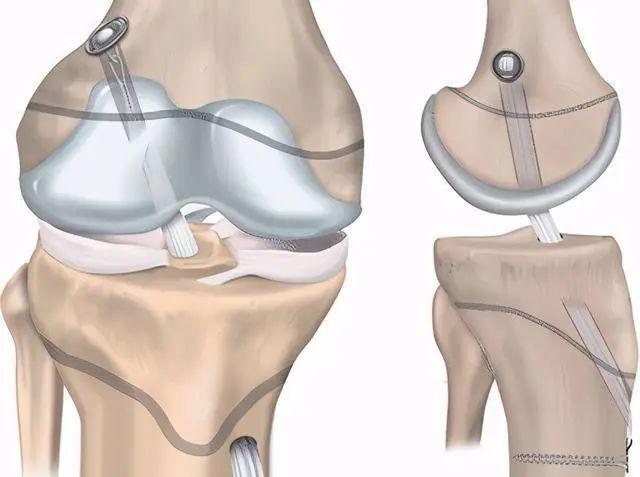

Artificial Joint Materials

Compared with materials such as ceramics and stainless steel, the elastic modulus of titanium alloy is closer to that of human bones, and it has more advantages in terms of modulus. Therefore, titanium alloys are widely used in the correction of ankle joints, elbow joints, etc. In addition, porous titanium alloy materials can make the prosthesis bioactive and help the healing of the femoral head; the surface of titanium alloy has good biocompatibility and can induce the growth of bone cells, so it is highly praised by clinicians and experts in the field of orthopedic,Widely used in the functional restoration of damaged or diseased joints such as hips, knees, shoulders or ankles.

Implant Prosthesis

The main advantages of titanium and titanium alloys as implant restorations are: ① high strength, good chemical stability and biocompatibility; ② non-toxic and will not cause harm to the human body; ③ low elastic modulus, better matched with human bones ; ④ Memory alloy has excellent elasticity and shape recovery function. In summary, the application of titanium in skull repair is mainly reflected in the use of titanium mesh to repair defective skulls. Applications in human cardiovascular aspects include: preparation of artificial heart valves, blood filters, pacemakers and artificial heart pumps, etc. At the same time, it is also widely used in spinal implants.

Dental Restoration

Titanium can be used for dental implants, and later for denture brackets, crowns, bridges, and orthodontic wires. Currently, titanium can be used for crowns, crown nails, fixed bridges, porcelain bridges, bonded bridges, denture clasps, bases, and connecting devices. and reinforcement devices, almost all metal components of dentures can be made of titanium. The research on titanium and titanium alloys has become a hot spot in dental application alloy research. Titanium alloy porcelain teeth can well restore the shape and function of teeth, and have high strength, beautiful appearance, stable color, smooth surface, wear resistance and corrosion resistance. It is a permanent restoration.

Medical Apparatus

Medical titanium medical instruments mainly include: scalpels, surgical forceps, surgical tweezers, chest expanders, suture needles, sutures, etc. Medical titanium wire is used as surgical suture. Compared with other materials (such as stainless steel wire), it has the advantages of small tissue reaction and good torsion resistance. After suturing, the surgical wound is less likely to become inflamed and the bone suture site is less likely to shift. Sutures generally use medical titanium wire (TA1 or TA2 wire) with a diameter of 0.5~0.8mm. In addition, the soft elasticity produced by titanium-nickel alloy wire can promote rapid wound healing.

In addition, medical titanium alloy is also an important material for auxiliary rehabilitation equipment, such as wheelchairs, crutches, splints, medical instruments, etc.

ENTORUST CERTIFICATION

We are follow the quality system and standards strictly.approvals from most leading OEM’s across Aerospace, Medical, Industrial, and Oil and Gas markets.

.jpg)