Chuangxin Road, High-tech Zone, Xi'an City, Shaanxi Province, China

Titanium Round Bar,Titanium Alloy Round Bar

Grade: GR.1, GR.2, GR.3, GR.4, GR.5, GR.7, GR.12, GR.23, Ti-6AL-4V, Ti-811, Ti-15333, Ti-6242, Ti-662, Ti-1023, Ti6246.

Specification:ASTM B348 AMS 4928 ASTM F67 ASTM F136

Diameter: Ø7mm-Ø230mm

Length: 30mm-600mm

DESCRIPTION

Titanium rods can be divided into pure titanium rods and titanium alloy rods. For pure titanium rods, we mainly provide grades such as Gr1, Gr2, and Gr4; for titanium alloy rods, we mainly provide rods such as Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, and Gr23.China National standard number: TA1 TA2 TA3 TA4 TA7 TA8 TA9 TA10 TA18 TB5 TB8 TB9 TB10 TC4 TC4Eli TC18 TC21 etc.

Titanium bar is one of the most common kinds of titanium products. It is the base material of many titanium products for further processing. The larger diameter titanium bar can be directly produced by forging. We have the free forging equipment which helps to produce the large size titanium bars. In the process of forging, the titanium ingot is deformed uniformly in a short time from inside to outside, improved the titanium mechanical properties. The material quality has been greatly improved compared to the hammer forging; Small diameter titanium bars can be produced after multiple rolling and annealing, and removed titanium oxide layer by mechanical processing in the end.

Titanium round bar is available in most of the almost 40 grades, with the most common being grade 5 and grade 2. The medical field often uses small-diameter round bar for body implantable fasteners and dental appliances. Round bar is made from very small diameters of wire for welding, all the way up to larger diameters (such as the 14″ diameter), used for clutch and flywheels.

State Supplied: hot processing state (R), cold processing state (Y), and annealed state (M)

Packing: Baled, or packed in the wooden case

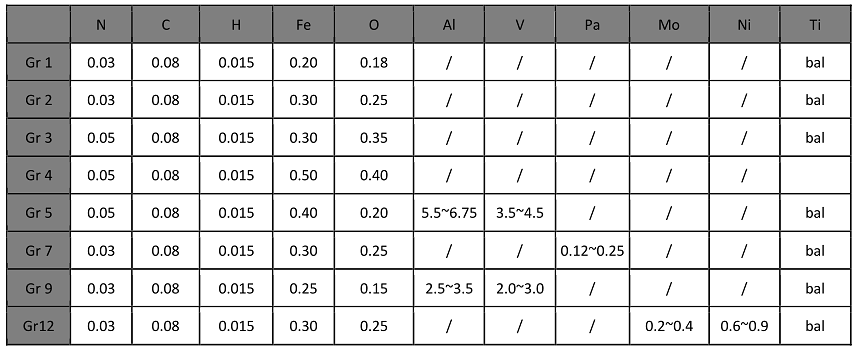

Chemical Component: (Nominal %)

Surface Treatment: Polishing or lathing

Surface Quality: The surface has high accuracy and is clean and smooth. No oxidized layers. No pits, cracks, backfins, rolling skins, lumps, laminations, hair cracks and other defects.

Physical Qroperties: Better elongation and strength

Test: Test on physical properties, hardness test and test on chemical ingredients.

Production Technology:

Flow of rolling production: Hot forging – Hot rolling – alignment – heat treatment – lathing (polishing) – physical and chemical tests – rating – warehousing.

Quality Control During Qroduction Process:

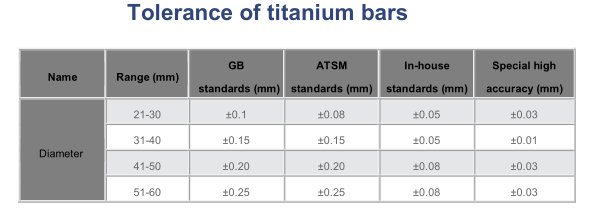

We use the first-class rolling mill and four-way high-speed forging machine for titanium bars. The production process strictly complies with relevant standards. The products’ dimensional tolerance and ellipticity tolerance meet China standards of GB/T2965-2007 and US standards of ASTM B348. Initial, in-process and final inspections are carried out to ensure high quality products.

Uses of Titanium Round Bar

Titanium bars are the most common titanium product. They are diverse and used in many applications in various industries.

·Jewellery

Titanium bars are used to create luxury pieces of jewellery. The titanium often makes jewellery fasteners that create secure clasps that maintain a lustrous finish for a long time.

·Aerospace industry

The aerospace industry is one of the largest consumers of titanium bars. Titanium is commonly used to make highly sensitive components. Bars are used to make the frame and some of the moving parts in the aircraft’s engine and propellers.

·Laptop computers

Titanium bars have a modern and shiny look that makes it ideal for making laptops. Computer brands, mainly Apple, have used titanium bars to make laptop bodies, among other components of high-end laptops.

·Armour

Titanium is lightweight and high strength. Titanium bars are often used to make fighter jets and other processes of making armour, while reducing the weight of the product and making it more durable.

·Medical

Titanium is in high demand in the medical industry. Our range of titanium bars is used to make dental implants, joint and bone replacements, surgical implants and an assortment of surgical equipment.

High-quality supplier of Titanium Round Bar

Entorust Titanium is a leading manufacturer and supplier of Titanium Bar, in a wide range of sizes grades and specifications. We can deliver the materials in stock lengths or we are able to offer cut-to-length services. Our in-house logistics team will ensure your order is accurately delivered on time, ensuring you can keep the tight deadlines of your project.

We maintain a complete inventory of titanium products,And we can also customize manufacturing according to special needs. we can provide customers with customized supply chain solutions through titanium alloy material management methods and project management capabilities.