Chuangxin Road, High-tech Zone, Xi'an City, Shaanxi Province, China

Titanium Is Important For 3D Printing

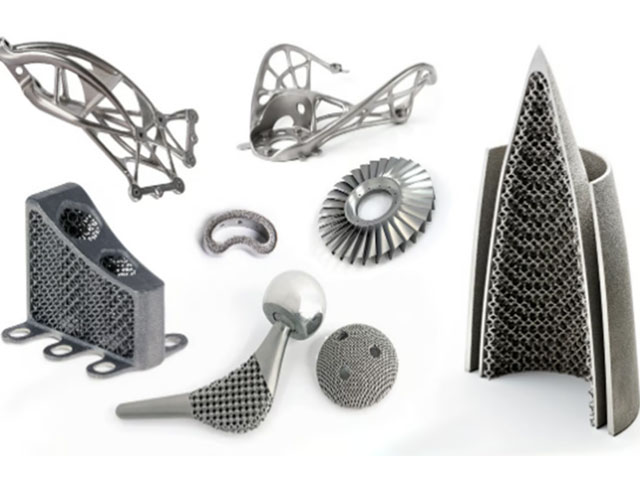

Titanium is one of the most commonly used metals in additive manufacturing. 3D printing technology can make this expensive metal more efficiently with lower raw material consumption and less scrap.

As a rapid prototyping technology, metal 3D printing typically uses only the amount of material needed to make the part, and relatively little support structure.

3D printing also enables complex designs such as internal channels, hollow or lattice-filled parts to reduce weight that cannot be surpassed by any other manufacturing method. Because no molds are required, 3D printing can produce unique parts.

There are a variety of 3D printing technologies used to machine titanium alloys, but the most commonly used is the powder bed fusion process using titanium powder.

Most titanium parts are manufactured using powder bed technology. Powder bed fusion technology is used to produce lightweight components for aerospace and racing as well as medical implants, while binder jetting technology is often used to produce smaller medical devices from titanium.

Additive Manufacturing Build Plates

Metal additive manufacturing build plates are an important part of the 3D printing world and are the basis for manufacturing precise metal parts. Their ability to be customized to specific thicknesses and their optimized surface properties make them ideal for ensuring excellent adhesion and precise dimensional fidelity throughout the printing process. In addition, these build plates facilitate efficient heat dissipation and effectively reduce deformation, ensuring the production of reliable metal parts.

ENTORUST CERTIFICATION

We are follow the quality system and standards strictly.approvals from most leading OEM’s across Aerospace, Medical, Industrial, and Oil and Gas markets.

.jpg)