Chuangxin Road, High-tech Zone, Xi'an City, Shaanxi Province, China

Titanium Elbow

Material: Gr1 Gr2 Gr7 Gr12 etc

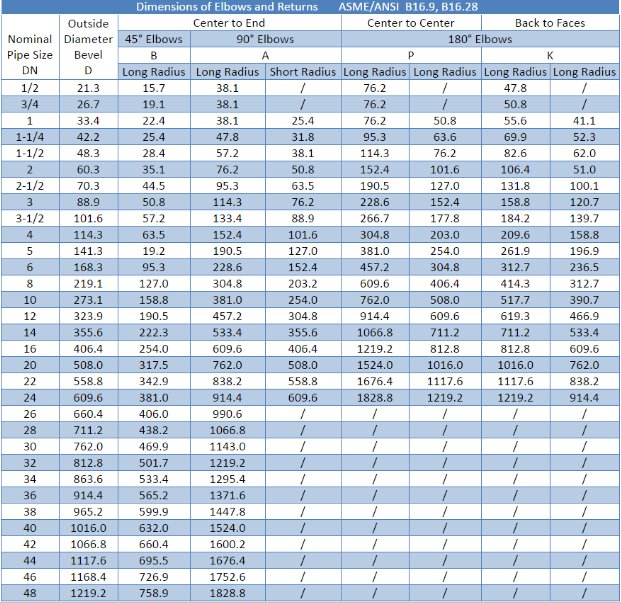

Standard: ASME B16.9 for titanium socket welding fittings ASME B16.11 for butt welding fittings and threaded fittings.

Size(mm): DN 1/2″-48″ (OD21.3-1219.2)

Fitting Types: socket welding fittings, Butt welding fittings, Threaded fittings

DESCRIPTION

In piping systems, elbows are pipe fittings that change the direction of the piping. According to the angle, there are three most commonly used ones: 45° and 90°180°, and other abnormal angle elbows such as 60° are also included according to engineering needs.

The characteristics of titanium elbow

Good corrosion resistance

Titanium elbows work in humid air and seawater media, and their corrosion resistance is significantly higher than that of stainless steel, and they are stronger in pitting corrosion, acid corrosion and stress corrosion.

Good low temperature resistance

Titanium alloys can still maintain their mechanical properties at low temperatures.

High strength

The density of titanium alloy is generally about 4.51g/cubic centimeter, which is 60% of steel, and the specific strength (strength/density) of titanium alloy is much greater than that of other metal structural materials.

High heat intensity

The titanium elbow can be maintained for a long time at 450~500°C, and the strength is high, but the specific strength of the aluminum alloy is reduced at 150°C, the working temperature of the titanium alloy can reach below 500°C, and the working temperature of the aluminum alloy can reach 200°C the following.

The surface is smooth without scaling layer, and the scaling coefficient is greatly reduced

The strength of titanium pipe fittings is higher than that of high-quality steel, and it has good heat resistance, low temperature toughness and fracture toughness. Titanium products are mostly used as parts and structural parts of aircraft and titanium equipment.

Dimensions of Elbows and Returns

Titanium Elbow application

Titanium Elbow are Widely used in chemical, petroleum, metallurgy, light industry, power generation, water desalination, medical apparatus and instruments, alkali, salt, electroplating, coking, chemical fertilizer, etc.

Titanium Elbow supplier

Entorust Titanium provide Titanium 45 Degree Elbows and Titanium 90 Degree Elbows in size Range of 1/2″ NB to 48″ NB. The Titanium & Titanium Alloy 45 ,90 Degree Elbows are manufactured in compliance with ASTM B363, and ASME B16.9. Titanium 45 Degree elbows can be either seamless or welded type intended for general corrosion – resistant and elevated – temperature service.

We maintain a complete inventory of titanium products,And we can also customize manufacturing according to special needs. we can provide customers with customized supply chain solutions through titanium alloy material management methods and project management capabilities.