Chuangxin Road, High-tech Zone, Xi'an City, Shaanxi Province, China

Titanium Seamless Tube Or Pipe

Ti Tube Standards: ASTM B338, B861, B862, DIN 17 861, AMS 4941, AMS 4942

Grade Material: CP Grades 1 – 4, Alloys: Grade 5, 7, 9, 12, 24, 26, 29

External Diameter: Ø0.5mm - Ø30mm

Wall Thickness: 0.5mm-10mm

Length: 30mm-15000mm

DESCRIPTION

Titanium Pipes are made up of different grades of titanium alloys. There are commercially pure grades of titanium and alloyed grades. Titanium Tubes and Pipes are available as Welded and Seamless form and in conformance with leading international standards including DIN, JISC, AMS, GB and ASTM (B338 B861 B862).Titanium is naturally strong and corrosion resistant. The titanium oxide which forms on the surface avoids further oxidation. There are seamless, welded, ERW and fabricated pipes and tubes.

Titanium Seamless Pipes Do Not Have Any Welded Joints Or Parts. These Are Directly Extruded Or Drawn From A Billet And Are Used In Industries Like Hydrocarbon Industries & Refineries, Oil & Gas Exploration & Drilling, And Hydraulic Cylinders, Bearings, Boilers, Automobiles, Etc.

The Titanium Seamless Tube is much smoother and has less absolute roughness. The seamless pipes can be used in precise applications such as equipment and instrumentation. The pipes come under different dimensions based on ASTM, ASME and API standards. Out of all the grades of titanium, the grade 5 is the most used. The Grade 2 Titanium Tubing is a commercially pure grade. The pipes range in nominal bore sizes from ½ inches to 24 inches generally. They also vary in pressure ratings and schedules. The schedules range from 10s to XXS.

State Supplied: M (acid washing and annealing)

Packing: Baled, or packed in the wooden case

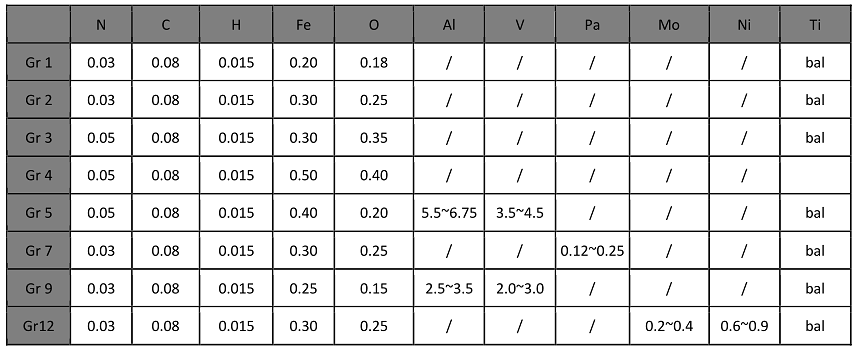

Chemical Component:(Nominal %)

Surface Treatment: The external and internal surfaces of tubes are washed by using nitric acid and hydrofluoric acid.

Surface Quality: The surface has high accuracy and is clean and smooth. No oxidized layers. No pits, cracks, backfins, rolling skins, lumps, laminations, hair cracks and other defects.

Physical Properties: Better elongation and strength. No deformation after cold bending. No cracks after flattening and flaring.

Test: Tensile strength test, flaring and flattening test, hardness test and test on chemical ingredients.

Production Technology:

High quality titanium tube blank – precision cold-drawing – vacuum heat treatment – ultrasonic flaw detection – high hydraulic pressure test – two ends sealed by the dust covers

Titanium Seamless Tube/Pipe Applications:

Titanium tube and titanium alloy tube is used in a wide range of applications including:

Hydraulic systems

Medical implants

Offshore dring

Subsea equipment

Chemical processing plants

Shipbuilding

Power machine building

Condensers

Heat exchangers

Nuclear power

Titanium Seamless Tube/Pipe manufacturer and supplier

Entorust Titanium is manufacturer and supplier of the Titanium Pipe in different grades and dimensions. We stock large quantities of the Titanium Tube in both seamless & welded at all time in our stock house. We supply the material to all big and small parties at any time they need. We export the Titanium Tube to all parts of the world. Our wide network and very good contact with supply chain managers enable us to deliver our products at any part of the globe. Tubing is a available as Coiled or Finned and manufactured to custom specifications.We provide a wide range of dimensions for the Titanium Tube and pipes so that they can fit to any size and shapes.

We maintain a complete inventory of titanium products,And we can also customize manufacturing according to special needs. we can provide customers with customized supply chain solutions through titanium alloy material management methods and project management capabilities.