Chuangxin Road, High-tech Zone, Xi'an City, Shaanxi Province, China

Titanium Wire,Titanium Alloy Wire

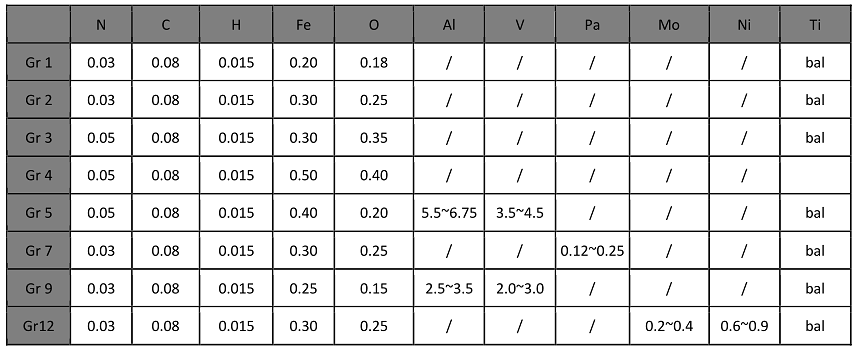

Grade: Gr1,Gr2 Gr3 Gr5 (Ti-6AI-4V),Gr7 (TI-0.2Pd),Gr9 (Ti-3AI-2.5V),Gr12 (TI-0.3Mo-0.8Ni),Gr23 (Ti-6AI-4V ELI) etc.

Specification: ASTM B863 ASTM F136

Diameter: Ø0.1mm - Ø8 mm

Length: 500-3000mm

Allowable Deviation: -0.125mm~ -0.14mm

Product Shape: Straight or coiled

DESCRIPTION

Titanium wire is a versatile and widely used form of titanium metal in industries such as automotive, aerospace, consumer goods, and defense. It can be produced in various forms and lengths to meet specific application requirements. Titanium wire is known for its strength, corrosion resistance, and high heat tolerance, making it ideal for use in tig welding equipment and hanging applications in the chemical processing industry.

State supplied: Annealed state (M), hot processing state (R) and cold processing state (Y) (annealing and ultrasonic flaw detection)

Packing: Air bubble film plus carton or wooden case

Chemical Component:(Nominal %)

Surface treatment: The surface is washed by using acid liquid and has smooth finish.

Surface quality: The surface has high accuracy and is clean and smooth. No oxidized color, cracks, peelings, burrs,spots or inclusions. Slight and local scratches, abrasions, spots and pits are allowed, but without exceeding acceptable tolerance of titanium wire’s diameter.

Physical properties: Better elongation and strength. No deformation after cold bending. No cracks after flattening and flaring. Wires with the diameter of over 3mm have no discontinuity, pores, laminations, cracks, and metal or non-metal impurities.

Test: Tensile strength test, macroscopic inspection, hardness test and test on chemical ingredients.

Technical requirements :

The ingots used for making wires should be smelted by the vacuum consumable electro-arc furnace for at least three times.

Production technology:

Titanium ingot – cogging – rolling – drawing – vacuum annealing – removing oxidized skin – physical and chemical tests – rating – finished product – warehousing.

Applications of Titanium Wire:

It is used frequently in aerospace and biomedical engineering.

Titanium wire is used for creating parts such as those found in vehicles, boats, and bridges.

Currently, titanium and titanium alloy wires make up more than 80% of all welding wires used in processes, including welding pipes, welding turbine disks and blades for aircraft jet engines, and welding casings.

Titanium wire has been widely utilized in chemical, pharmaceutical, papermaking, and other sectors because of its exceptional corrosion resistance. In addition, it can be turned into a mesh for a chemical drug filter, a seawater filter, or a purified water filter.

Titanium and titanium alloy wires are also used to make fasteners, load-bearing parts, and springs.

Because titanium and titanium alloy wires work well with the body, they are used to make medical devices like pacemakers, defibrillators and battery components.

The manufacture of satellite antennas, clothing shoulder pads, women’s bras, and eyeglass frames utilize titanium alloy wires with shape-memory properties.

Wires made of titanium and titanium alloys are used to create a variety of electrodes in the electroplating and water treatment sectors.

Titanium Wire supplier

Entorust Titanium are a fully stocked global Titanium Wire supplier , and we make it easy for you to find the product you need with quick shipments! If you require Titanium Wire, consult us soon!

We maintain a complete inventory of titanium products,And we can also customize manufacturing according to special needs. we can provide customers with customized supply chain solutions through titanium alloy material management methods and project management capabilities.