Chuangxin Road, High-tech Zone, Xi'an City, Shaanxi Province, China

Titanium Flange

Grade : Gr1 Gr2 Gr5 Gr7 Gr9 Gr12 etc.

Specification : ASTM B348 , ASTM B381 , AMS4928,AMS9047, AMS4973, AMS4975, AMS4976, AMS4978, AMS4979, AMS4981.

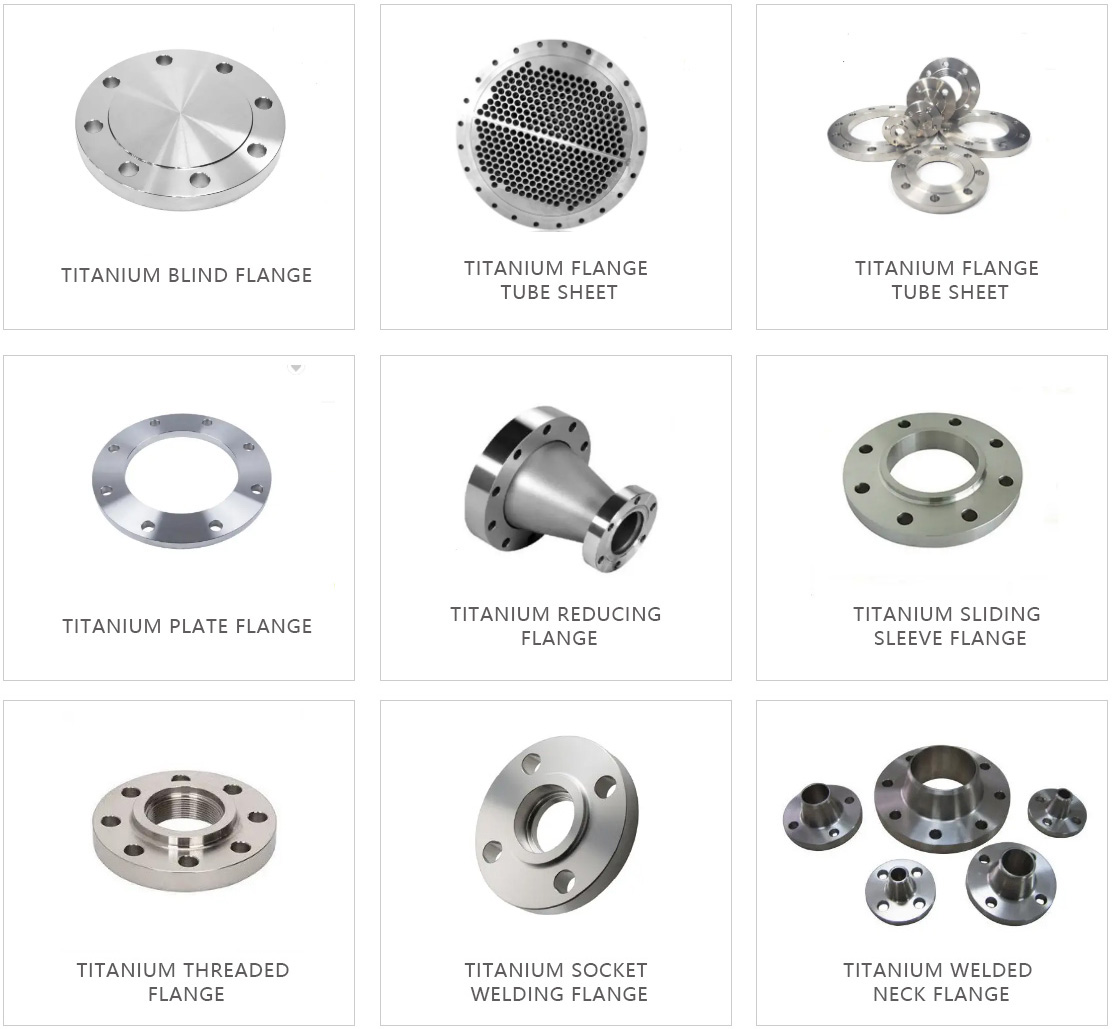

Products: titanium blind flange, titanium flange tube plate, titanium lap joint flange, titanium plate flange, titanium reducing flange, titanium sliding sleeve flange, titanium threaded flange, titanium socket welding flange, titanium Welding neck flange etc.

DESCRIPTION

Titanium Flanges are used to connect pipes, pumps, vales and other piping components together to create a piping network. They are used to split pipe networks to facilitate inspection and cleaning, and can be either screwed or welded to pipes. Flanged joints are typically bolted together with a gasket in between.

There are holes on the Titanium Flange, and the bolts connect the two titanium flanges tightly. The titanium flanges are sealed with gaskets. Titanium Pipe fittings refer to pipe fittings with flanges (lugs or adapters).

It can be cast, threaded or welded. The flange connection is composed of a pair of titanium flanges, a gasket and several bolts and nuts. The gasket is placed between the two titanium flange sealing surfaces. After tightening the nut, the specific pressure on the gasket surface will deform after reaching a certain value, and fill the uneven parts on the sealing surface to make the connection tight.

Different materials and different specifications of Titanium flanges have different functions. In the material classification, industrial pure titanium TA2 flanges are more commonly used, titanium alloy flanges TC4 titanium alloy flanges, TA9 titanium alloy flanges, TA10 titanium alloy flanges, etc. are used in different environments. Lasting New Material(Lasting Titanium) can produce various types of titanium flanges according to customer requirements. According to the different fluid media, and referring to the requirements of materials such as corrosion resistance and supporting pipelines, the best cost-effective products and Titanium Flange pipe fittings can be selected under different circumstances. Combined use to achieve an excellent fluid pipeline solution.

Types of titanium flanges

Pipe flanges can be divided into eight types based on design.

Titanium Weld neck Flanges

Weld neck flanges, also known as high hub flanges or tapered hub flanges, are designed to be connected to piping systems by butt welding. Welding neck flanges is preferred when the pipe is subjected to high stress, high pressure or sub-zero/high temperature. The neck, or hub, helps to transfer environmental stress to the welding of the flange and pipe. The gradual transition from hub base to butt-weld wall thickness provides significant reinforcement for the flange, and turbulence and erosion are reduced due to the matching inside dimensions of the pipe and flange. These flanges are bored to match the inside diameter of the supporting pipe and therefore do not restrict flow.

Titanium Lap Joint Flanges

Almost identical to the slip-on flange, but with a radius at the hole and the flange face intersecting to accommodate a lap stub end. These flanges slide on the pipe without other welding or fastening to it. The bolt pressure is transmitted to the gasket through the flange to the back of the pipe lap. The surface on the short end forms the gasket surface of the flange. Lap-Joint flanges have no raised surface and a single connection requires lap flanges and a pipe stub-end. They are most suitable for parts of the piping system that require quick and easy removal for inspection or replacement.

A lap joint flange is used with a matching stub-end inserted inside. The main advantage of this type of flange is that once the pipe is welded to the inserted stub-end, the flange can then rotate for easier alignment of the bolting holes.Lap joint flanges are mainly used in piping systems requiring frequent dismantling for inspection and cleaning.

Titanium Socket Weld Flanges

Similar to slid-on flanges in design, but with a hole that is counter boring to accept pipes. The diameter of the remaining holes is the same as the inside diameter of the pipe. Fillet welding around the flange hub connects the flange to the pipe. Optional interval welding can be used for high stress applications. Its greatest use is in high pressure systems, such as hydraulic and steam pipes.

Titanium Slip On Flanges

Slide through the pipe and then weld from the inside and outside to provide sufficient strength and prevent leakage. This flange is used by many users in place of welding necks because of its lower cost and because it requires less precision when cutting pipes. Sliding sleeves are usually not used in high-stress applications due to low hubs and welded attachments.

Titanium Blind Flanges

Blind flanges have no bore and are used to close openings in piping systems or vessels. It is designed for easy access to ships or piping systems for inspection. It can be offered with or without a hub in the manufacturer’s choice. Blind flanges, especially those of large size, are the most stressed type of flange in terms of internal pressure and bolt load.

Titanium threaded Flange

Suitable for special environments, its main advantage is that it can be connected to the pipe without welding. Sometimes seal welds are also used with threaded connections. Although threaded flanges are suitable for most sizes and pressure classes, they are now used almost exclusively for smaller sizes of pipes. Threaded flanges are not suitable for pipes with thin wall thickness because it is not possible to cut threads on pipes.

Titanium flanges application

Titanium flanges and titanium alloy flanges are mainly used for corrosion-resistant pipes, valves, pumps, corrosion-resistant structural parts and stamping parts, parts of seawater desalination systems, chemical heat exchangers, pump bodies, distillation towers, cooling towers, Fluid interface accessories such as agitators. In many media, titanium flanges have excellent anti-corrosion ability, acid and alkali resistance, long service life, low density, high strength, light weight of equipment, smooth surface, low fouling coefficient, etc., and can achieve high efficiency and energy saving in application.

Titanium Flange manufacturer and supplier

Entorust Titanium is a leading manufacturer and supplier of Titanium Flange, in a wide range of sizes grades and specifications.

We maintain a complete inventory of titanium products,And we can also customize manufacturing according to special needs. we can provide customers with customized supply chain solutions through titanium alloy material management methods and project management capabilities.